Shinda Creative? offers high-performance, corrosion-resistant, reliable hydraulic control lines with a wide range of tube materials and sizes for specialized applications such as downhole hydraulic control line, chemical injection line, subsea umbilical control lines, smooth bore control lines, instrumentation and more. We can customize 6000 Meters Ultra Length Seamless Tube without Girth Welding.

As a world-leading manufacturer of control lines, Shinda Creative? provides a wide range of high strength stainless steel and alloys, such as austenitic stainless steel, duplex stainless steel, nickel-based alloy, Monel alloy?tubes and size is from 1/8” to 1”. Other alloys, sizes and options can be manufactured according to your requirements.

The Oil & Gas sector represents one of Shinda Tubing principal markets for supply of a wide range of tubular product forms and materials. Our control line products have been successfully used in some of the most aggressive subsea and deep sea conditions and we have a long proven track record of supplying products that meet the strict quality requirements of the Oil & Gas and geothermal energy sectors.

Advancements in technology for the efficient exploration and extraction of oil and gas have increasingly necessitated the use of long, continuous lengths and zero defects of stainless steel and nickel alloy tubing. This tubing is essential for applications such as hydraulic control, instrumentation, chemical injection, umbilical systems, etc.

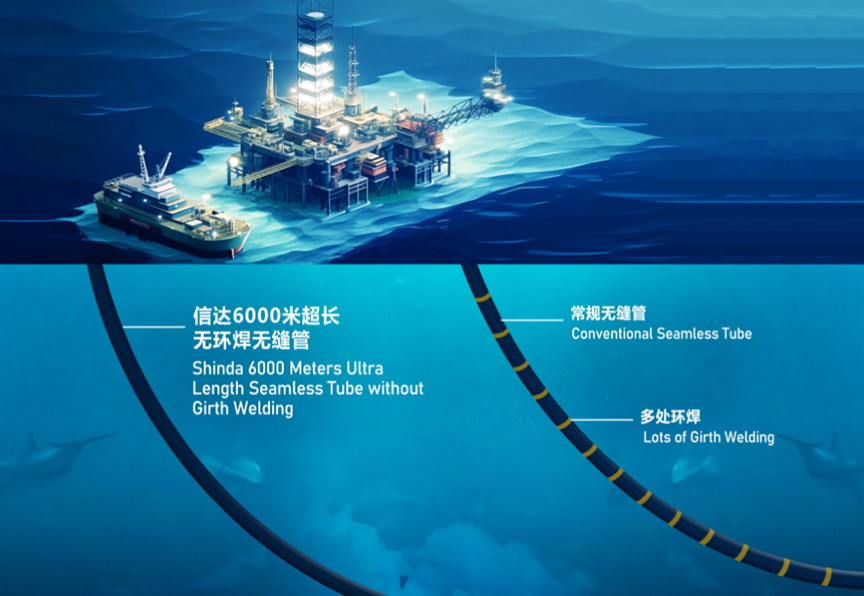

Shinda can customize engineering Hi-tech (IP 71202220093537.7) 6000 Meters Ultra Length Seamless Tube without Girth Welding which is the best solution to withstand offshore unforgiving challenges like high temperatures, high pressures and extreme corrosion.

Shinda Creative? is your best choice!

1. Strong, Safety, Reliable

Our hydraulic control lines can be used in different environments, especially the most difficult environments such as high-temperature corrosion, ultrahigh pressure environments;

2. High-Quality, Long Service Life

With our quality control system, all of our control lines meet the strict quality requirements of the Oil & Gas and geothermal energy sectors, and have longer service life;

3. 6000 Meters ultra length control line

We can manufacture and produce up to 6000 meters ultra length seamless tube withou girth welding;

4. Reduce Your Operation Cost

Your operation cost and maintenance cost can be reduced by the installation of reliable, safety, and long service life control lines;

5. Customizable

We can manufacture hydraulic control lines according to your requirements;

Our products can be used in hydraulic control, instrumentation, chemical injection, umbilical and flowline control applications, etc.

Ultra Length Seamless Tube

Shinda Creative? customizes engineering Hi-tech (IP 71202220093537.7) 6000 meters ultra length seamless tube without girth welding, effectively solve conventional seamless tube potential welding internal burrs and groove corrosion, avoid welding defects like partial welding and lack of weld, which multiplies increase product life and reliability for more benefit to customers with superior cost savings.

6000 Meters Ultra Length Seamless Tube Without Girth Welding is the best solution to withstand offshore unforgiving challenges like high temperatures, high pressures and extreme corrosion.

?

Seamless Control Lines

A seamless tube that has been cold worked and annealed has a completely homogeneous crystalline wrought structure.There is a longitudinal weld with seamless tube although orbital welds are used to manufacture long lengths. The manufacturing process for the seamless tube limits the maximum continuous length, therefore orbital welds are required to join lengths of seamless coil together to achieve lengths that are suitable for well applications.

Welded and Drawn Enhanced Control Lines

In the welded and Drawn production process, we will enhance the welded tube tensile strength,yield strength,hardness through special annealing process, So that it can withstand higher internal working pressure under a thin wall thickness, which has the advantages of reducing weight, improving energy efficiency, improving safety and reliability. At the same time, the wear resistance, load weight, hardness and other properties of the pipe will also be improved, more suitable for high pressure and high load occasions.

Welded & Floated Plug Drawn Control Lines

After the welding process, the tube is drawn through a die that has a floating plug inside the bore to refine the weld seam. This plug is not attached to a rod or mandrel; instead, it "floats" in the tube, surrounded by lubricant. The die reworks the weld seam to improve surface roughness, truly round outer diameter (OD). This type of tubing is referred to as "smooth" bore.

Welded and Drawn Control Lines

After welding, the tube is drawn through a reduction die to homogenize the seam weld. The weld seam is reworked externally by the die. By drawing through a die, the tube has an improved sealing surface, and a truly round OD and an improved external surface finish. This is most popular used in well site.

| Material | ST316L-40 | ST2205-80 | ST2205-90 | ST2507-90 | STB 25-40 | ST625-40 | ST Monel 400-40 | |||

| Chemical composition | Cmax | 0.03 | 0.03 | 0.03 | 0.03 | 0.05 | 0.10 | 0.30 | ||

| Mn max | 2.00 | 2.00 | 2.00 | 1.20 | 1.00 | 0.50 | 2.0 | |||

| Pmax | 0.045 | 0.03 | 0.03 | 0.035 | ... | 0.015 | ||||

| Smax | 0.03 | 0.02 | 0.02 | 0.02 | 0.03 | 0.015 | 0.024 | |||

| Simax | 0.75 | 1.00 | 1.00 | 0.80 | 0.50 | 0.50 | 0.50 | |||

| Cr | 16.0-18.0 | 22.0-23.0 | 22.0-23.0 | 24.0-26.0 | 19.5-23.5 | 20.0-23.0 | ||||

| Nim in | 10.0-14.0 | 4.5-6.5 | 4.5-6.5 | 6.0-8.0 | 38.0-46.0 | 58.0 | 63.0 | |||

| Mo | 2.00-3.00 | 3.0-3.5 | 3.0-3.5 | 3.0-5.0 | 2.5-3.5 | 8.0-10.0 | ||||

| Cu | ? | ? | 28.0-34.0 | |||||||

| Femax | ? | ? | 2.6 | |||||||

| Yield Strength(min) ,? psig | 40,000 | 80,000 | 90,000 | 90,000 | 40,000 | 40,000 | 40,000 | |||

| Tensile Strength(min) ,? psig | 70,000 | 95,000 | 95,000 | 116,000 | 85,000 | 100,000 | 70,000 | |||

| Hardness,? HRC | 200HV | 30 | 30 | 32 | / | / | / | |||

Thanks for your interest. To receive more product information, price, catalog, etc. Please fill out the form bellow. We will get back to you within 24 hours.